Interview with Logitech’s Head of Sustainability, Robert O’Mahony

Table Of Contents−

- You started at Logitech 20 years ago. Can you tell us what was happening then and what has changed?

- Why was sustainability a passion for you?

- What's changed in the past few years, for Logitech and the industry?

- As we look at Logitech's new products, what would you say shows the change in attitude as opposed to five years ago?

- To put that number into context, do you have any idea what kind of fraction that is of Logitech's global total?

- So what about your products themselves? In terms of recyclability and repairability, what do you aim for now when you launch a new Logitech product?

- Will these changes come with an increased cost to the consumer?

- And will that mean products have to be bigger?

- You've worked at this for 20 years, so what about the next 20 years? What do you hope the industry and Logitech have achieved by 2043?

- Additional coverage on sustainability

There’s nothing quite like speaking to someone who believes in what they do. Is truly passionate about it. As you will discover in this interview with Logitech’s Head of Sustainability, Robert O’Mahony is one such person.

When you read some of his responses, you may think this was a long-planned interview where Robert was given the questions in advance. In fact, he happened to be attending a Logitech product showcase last week, so I took the opportunity to ask him some questions.

What rapidly became clear is that sustainability has fuelled Robert’s 20-year career at Logitech, even if the term has only recently become common. To provide some context, when he joined Logitech in November 2003, the phrase “circular economy” didn’t even exist. (Gretha Thurnberg hadn’t even celebrated her first birthday.)

It’s thanks to Robert and his team that when we recently wrote an article “Is Logitech a green and sustainable company?” the answer was yes. But he is determined to do even more in the next 20 years — and for the whole industry, not just Logitech.

You started at Logitech 20 years ago. Can you tell us what was happening then and what has changed?

I was actually hired to help Logitech grapple with the first piece of environmental regulation that was beginning to hit our industry, RoHS. It was like the beginning of everything.

Within a couple of years, I saw that there was an appetite within the company to go well beyond regulation. So I’ve overseen much of that, where we’ve gone from a place of regulatory compliance, through to doing the right thing and going beyond — really trying to motivate others and act as, let’s say, a lighthouse brand for others to be more sustainable.

Why was sustainability a passion for you?

I actually studied biochemistry and microbiology, so my original background was life science. But I grew up in a rural part of Ireland, and I always had a grá — a very Irish word — this kind of attraction to the outdoors. I guess nature reared me. And from that I had this incredible passion for ensuring that we protected our natural world.

When I graduated, I had studied quality control as a minor subject. I ended up working in the electronics industry more in quality, but actually, that triggered my second passion for technology. An opportunity presented itself [at Logitech] to blend those two passions to make an industry sector I loved behave more responsibly.

What’s changed in the past few years, for Logitech and the industry?

Consumer sentiment. There’s a realisation within the consumer mindset, that if they invest in a product, there’s an expectation via that investment that the product hangs around.

I remember an advertisement in, I think, Popular Mechanics [magazine] in the 1970s, for this TV repair kit. It was like a CRT TV, so one of those big cumbersome guys, and you could build it and you ended up with a TV but you also ended up with a skill, a repair skill. I’m also old enough to remember TV repair shops: they were a thing, they’re no longer a thing. Or at least they’re few and far between. I think there’s a realisation that we had it right. Before, we were on the right track.

The TV I buy today is not designed for repair. It’s not designed for longevity. It lasts as long as it lasts, and when it’s gone we “responsibly” recycle it. We take some of the material back but, in reality, no-one gets to repair it. And I personally have an issue with that.

I harp for the old days when we valued the products that we made, and I’m not the only one. I think that’s been a fundamental change.

As we look at Logitech’s new products, what would you say shows the change in attitude as opposed to five years ago?

So the big one, for sure, is the fact that we’re acknowledging that second-life material is just as good as virgin material. It can be utilised in a manner where the consumer gets the same experience, the same price point, standard availability, there’s no compromise there. But what we’re doing is we’re pulling from a supply chain that was previously labelled as waste. So we’re using somebody else’s waste as a raw material.

And what that’s doing is significantly reducing our footprint. I’ll give you a couple of data points. In the last year, we shipped about 150 million products. Two-thirds of those were made with recycled materials of some sort or another, primarily PCR [post-consumer recycled] plastics.

That’s about 100 million products, and in those 100 million products that eliminated about 27,000 tonnes of our carbon equivalent from our footprint. But it’s also beginning to decouple our relationship with oil because oil is plastic. And we avoided the use of about 9,000 tonnes of virgin plastic, which has to be extracted, mined, refined.

To put that number into context, do you have any idea what kind of fraction that is of Logitech’s global total?

Right now, we’re about 1.2 million tonnes total — that’s all of Logitech, that’s all the 150 million products, it’s all our offices, it’s all our manufacturing, it’s all our packaging. So it’s a long way to go. But in reality, when you create programmes like that they repeat every year and they also create this kind of carbon intensity scenario where, as we grow, the cost of the carbon associated with our growth reduces over time.

So what about your products themselves? In terms of recyclability and repairability, what do you aim for now when you launch a new Logitech product?

We look at all of that under the banner of circularity. And for us, circularity means two things. It means recovering material, creating a circular supply chain where there once was a linear one. PCR is a really good example. There are others, component recovery and so on.

And then the other piece of the equation on circularity is life extension, repairability and so on. We’ve intentionally focused on the first piece, right. We’ve done a lot on that. We’re beginning on the other piece.

I would say that [our partnership with] iFixit was a stake in the ground for us to say that we’re now engaging in a very public way on a limited number of products because we need to learn. It’s a different muscle when you’re supporting a circular supply chain versus supporting a linear supply chain. So we need to build that capability. That’s our intention: to design for repairability.

Will these changes come with an increased cost to the consumer?

Not necessarily. I would say, first of all, we’re very conscious of the relationship we have with our consumers. We’re very aware of scenarios out there in the world, where maybe some brands are differentiating on sustainability, and driving a premium for that. That’s not what Logitech does, and I’ll tell you why I know that for sure: because we’ve been providing our products with post-consumer recycled plastic long before we started talking about it. Long before. And we did it in a way that didn’t impact negatively on the consumer experience, cost, availability, technological factors, and so on. That’s the first thing.

I think the second thing is we have scale. So what we’ve managed to do is we’ve managed to utilise our scale to allow us to present a sustainable alternative at the cost point that’s expected by the consumer.

And will that mean products have to be bigger?

Yeah, this is interesting. So as you know, the EU right now is talking about an eco-design directive and the battery directive and so on. And there are so many considerations being given to the fact that today, for the most part, if you have a battery-encapsulated product, it’s usually a soft pack, right? So it’s not anticipated that it would ever be repaired by the consumer.

If you want to provide a consumer repair option, that becomes a hard shell, and that takes up more space. But here’s the reality. The reality is we don’t look at space and we don’t look at volume or weight as an indicator of progress. We look at carbon, we look at toxicity, we look at circularity, we look at water, we look at energy, so we look at all those indicators to determine the progress that’s made.

So my team has what’s called an LCA or lifecycle analysis capability in-house, that allows us to interrogate Design A versus Design B versus Design C in the overall product lifecycle. That’s in source, manufacture, supply to market, consumer use and end of life. We look at the entire lifecycle of the product and determine what its impact is. And invariably what happens is if you have a product that was designed for battery replacement, and you have to maybe use a more carbon-intensive battery to achieve that, in reality, all you’re doing at the end of the life of that product is replacing the battery not replacing the battery and the product.

You’ve worked at this for 20 years, so what about the next 20 years? What do you hope the industry and Logitech have achieved by 2043?

So what I’m hoping for is our society to have adopted personal responsibility around the impact that you and I can have as consumers, because we actually decide what brands succeed or fail. If you think about it, we go and buy those brands, or we support those brands. And I’m hoping for a time where we’re informed enough to engage with brands who are making a difference, and I’ll tell you how Logitech is actually attempting to do that.

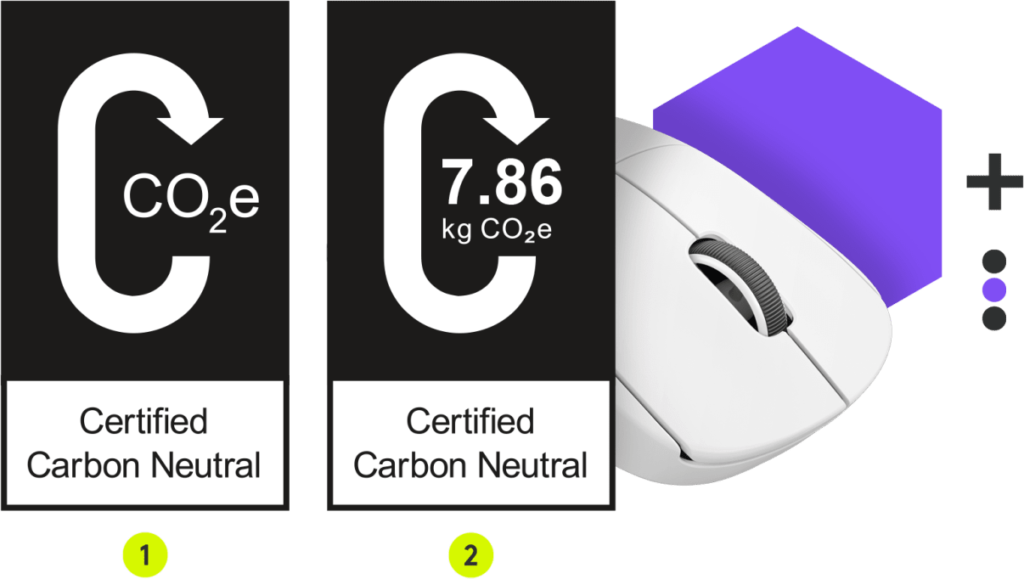

So we have a carbon transparency labelling programme called carbon clarity, where we in essence have committed by 2025 to provide the carbon footprint on all of our products at the point of sale or consideration.

We’re attempting to mimic carbon as the new calorie, to provide the consumer rights scenario where, let’s say, if you or I were to go to a store this evening, and we picked up a packet of crisps and there was no nutritional value there, we’d be kind of cautious, right? We’d be a little concerned if that was missing because that’s a consumer right for us to know. Well, we feel that it’s the consumer’s right to know what the carbon impact is, or the environmental impact is, of their products.

And here’s the kicker, right. This is actually our objective. We don’t necessarily want to stand out from the market by being the company that does that. We want to be the catalyst for others to do that, so we compete on the basis of that carbon value.

Because imagine you as a consumer, you go into whatever store and you decide you’re going to buy a keyboard, and you have this plethora of keyboards. Each of them has this value and you decide, you know what, I want to do the right thing and get the lowest impact one. Guess what’s gonna happen to the person who missed out on the sale? They’re going to innovate, to exceed [the current standards].

Now that requires standardisation and measurement and so on, but ultimately I’d like for us to be part of a society where we’re fully informed, where transparency is the new green, where I know the provenance of where my products come from, the impact they’ve had. Where I know that the brand has been utterly honest with me about about all that. And then I decide whether or not I want that brand in my life.

Additional coverage on sustainability

NEXT UP

Panos Skliamis, CEO of SPIN Analytics: “It’s important to see the changes we’re living through in the context of the transformations that have come before”

We interview Panos Skliamis, CEO of SPIN Analytics, an AI-driven platform that automates credit risk management and regulatory compliance

Why hiring for skills future proofs business operations in cyber and tech

For business operations in cyber, hiring based solely on previous experience and formal education is no longer practical, argues Ev Kontsevoy.

Riken to integrate IBM’s quantum system with supercomputer Fugaku

IBM and Japanese laboratory Riken have announced an agreement to deploy IBM’s quantum system and integrate it with supercomputer Fugaku